You are here: MoTion Control Weld

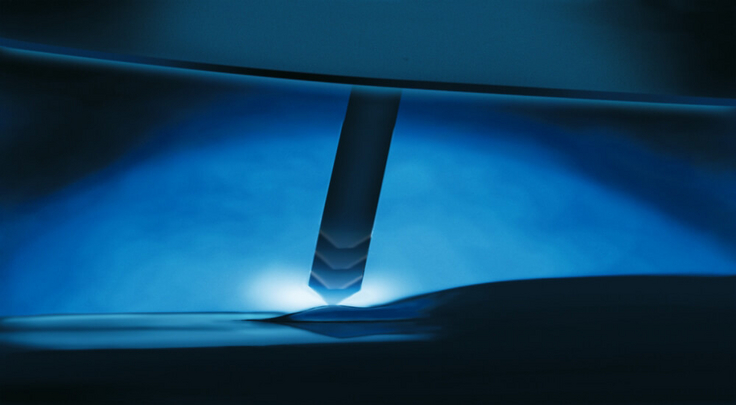

MoTion Control Weld

MoTion Control Weld is a controlled short arc with reversing wire drive unit. It is a combination of a classic Control Weld process in the short arc range and a mechanical system which draws the wire back and forward at a high frequency. Thus short circuits can be interrupted cleaner and with less energy than in the case of short arcs without reversible wire electrode. Due to the low heat input into the workpiece and the minimised spatter formation at high welding speeds the stable process is particularly suitable for thin plate applications.

Your contact person

Christian Paul

Tel.: +49 (0)2773/85-565

These processes could interest you

Tandem Weld

Combination of two synchronised MIG/MAG arcs for double capacity

Rapid Weld

High-capacity MIG/MAG spray arc for efficient welding

Cold Weld

Heat-reduced MIG/MAG AC pulsed arc for optimum results when welding sensitive materials

Laser Hybrid Weld

Combination of laser welding and MIG/MAG arc for maximum efficiency and quality